Materials Testing

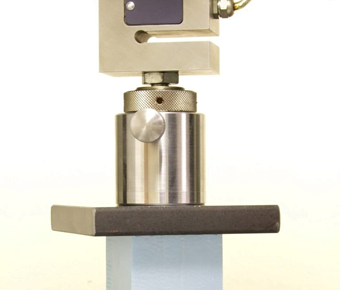

For any material to be fit for service, an in depth understanding of its properties and characteristics under the conditions of service is vital. UKAS Accredited Materials testing plays a major role in the selection and development of engineering materials across all sectors and applications and drives the continued innovation of new materials for the increasingly demanding applications of advanced technologies.

The UKAS accredited laboratories at Testing House provide extensive facilities for testing the properties of engineering materials such as adhesives, rubbers, ceramics, polymers, composites, welds and metallics, as raw material or in finished forms and products.

Product Approval and Certification

Many of our clients require their materials to be tested to meet the standards and specifications of their industries. In some cases, the certification bodies themselves select R-TECH as their chosen partner for their certifications and accreditations.

Our experienced technical teams are competent in preparing and delivering testing to the details of international or national standards as well as industry or in-house specifications. All of our testing equipment can be easily adapted to meet the requirements of your specification or certification body and where appropriate our technical team will work closely with our on-site workshop to manufacture the jigs or fixtures that your product or material might require.

Characterisation & Development

Many of our clients depend on our testing expertise as they seek to develop their products and bring new materials, components or products to market. We will advise you on the best tests to understand your material’s properties and can help to design and implement a cost effective testing program.

Routine Testing, Investigation & Analysis

Whilst the focus of most material testing is on bringing materials to the marketplace, many industries require the ongoing testing of materials, particularly in safety critical applications where a reduction in quality could have a significant impact on performance or safety.

We regularly complete routine testing and batch testing on materials and products alike but can also apply our materials expertise and testing skill to investigate and analyse quality or manufacturing issues and product or materials failures.

Product Testing

Wakeboards, bolts, fasteners, aeroplane interiors, bus seats, electrical components, deodorant cans, karabiners even garden spades; our product testing technicians have seen it all. You can read specifically about our product testing experience here.

Static Properties (Destructive)

Static Properties (Non-Destructive)

Fatigue Properties

Thermal Properties

Chemical Properties

Environmental Properties

Creep Properties

Seismic Properties